Why it needs to make new molds if you want to emboss (Engrave) logo on the rotomolded coolers?

Many customers want to emboss (Engrave) logo on the rotomolded ice chest coolers. Like Yeti coolers, RITC COOLERS and so on.

|

|

|

|

|

|

Many customers have questions that why you don’t make movable logo plate blocks? Then it can change to any customer’s logo.

Lid mold(Top and inside),we suggest only make lid mold |

Base mold(Inside and Bottom),we don't suggest |

Join Boright (Hengli): Hong Kong Outdoor Show 2024 Awaits!

Join Boright (Hengli): Hong Kong Outdoor Show 2024 Awaits!

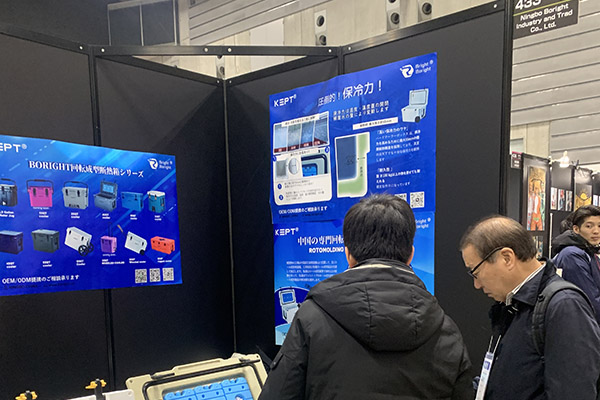

Boright Celebrates Triumph at Japan Intersyle outdoor show 2024

Boright Celebrates Triumph at Japan Intersyle outdoor show 2024

Boright 2024 Japan exhibition(Feb 13-15) booth 433 at PACIFICO Yokohama

Boright 2024 Japan exhibition(Feb 13-15) booth 433 at PACIFICO Yokohama

Boright(Hengli) 2024 Exhibitions plan for outdoor camping coolers

Boright(Hengli) 2024 Exhibitions plan for outdoor camping coolers